What is the TR19 Grease specification?

BESA (Building Engineering Services Association) have updated TR19, the duct-work cleaning guidelines for internal cleanliness of ventilation systems.

Since the introduction of TR19 there has been a higher awareness of cleanliness in supply ventilation and kitchen extract ductwork. The new TR19® Grease specification for Fire Risk Management of Grease Accumulation within Kitchen Extraction Systems issued in July 2019 raises the standard for duct cleaning.

Why is it important?

Those who work with food businesses including Mechanical & Electrical Consultants & Engineers, Ventilation & Canopy Specialists, Planning & Environmental Health Officers, Facilities Managers & Landlords, know how hard it can be to control grease build-up in the kitchen ventilation ductwork.

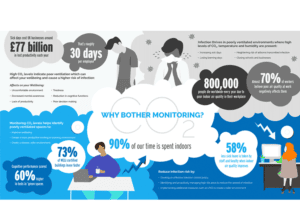

Failure to comply with the new TR19 Grease specification means that you also fail to control fire risk.

A TR19 assessor will take measurements of grease deposition at various points within the duct. An average of 200 microns thickness (about half the thickness of an average business card!) means the whole duct needs to be cleaned and any regions of 500 microns or more need spot cleaning. The duct may not always be accessible, so duct cleaning isn’t always possible.

The risks

Should a kitchen extract ductwork fire occur, smoke and flames can be carried through the ductwork to cause damage throughout the building, putting lives in risk. Buildings insurance can also be compromised.

Here at Plasma Clean, we still see many ventilation and kitchen extract systems with grease control issues. Gladly, we have a wide range of trusted solutions for you.

What are the solutions?

As well as products to stop grease build-up in the first place, we now have our new TR19 duct inspection and cleaning service . With this unique blend of products and services we can help commercial kitchens save on duct cleaning and kitchen shutdowns as well as preventing fire risk.

The trusted solutions include:

- TR19 inspection and cleaning: Operating nationwide and ready to attend site now. Contact us HERE>

- Coil filters: Capture oil & grease in extraction canopies. Designed to capture 95% of grease particles. For more info CLICK HERE>

- ESPs: Highest particulate removal efficiency, up to 98% per pass CLICK HERE> If you have an odour issue as well, CLICK HERE>

- Techniclean: A slim-line in-duct unit designed to break down grease (and odour) combining high intensity UV-C light with ozone technology CLICK HERE>

Maintenance is important

In kitchen ventilation, depending on the level of grease and smoke in the cooking process, the ductwork and grease control solutions require a cleaning regime. On average, this takes place every 3 months. We pride ourselves on the quality of not only our equipment but the level of maintenance offered.

Here at Plasma Clean, we’re experts on fire prevention in commercial kitchens. To learn more about the steps you can take in your own kitchen, you can request a copy of our free guide on ‘How to prevent commercial kitchen ventilation going up in flames’. FREE GUIDE REQUEST>

You are welcome to contact us today about how our solutions can prevent fire risk:

Tel: +44 (0)161 870 2325

Email: [email protected]

Dr David Glover is Co-founder and Managing Director of Plasma Clean. Since the start of his career, David has had an interest in creating a cleaner, safer environment. His original research focus was on how micro-organisms break down pollution in the environment. This led to a doctorate in environmental microbiology. He’s been involved in the technology sector since 1996, and now leads all Plasma Clean R&D activity.