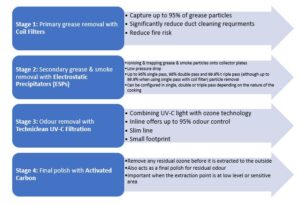

DW/172 Specification for Kitchen Ventilation Systems was published in January this year. Carbon filtration is ‘increasingly not accepted by Local Authorities as the primary means of odour control’. UVC (and ozone) are now the preferred solution to reduce cooking odours.

What is UVC?

UVC stands for Ultraviolet light in the C-band. A very strong type of ultraviolet light. UVC Lamps create high intensity light energy (photons).

Light energy reacts with the grease and odour molecules, causing them to break down. The chemical reaction is known as photolysis. Plasma Clean use UVC lamps in our Techniclean and ESP/UV ranges.

UVC lamps also create ozone. When ozone is released it oxidises the molecules, in a process known as ozonolysis. Plasma Clean Xtract series create ozone and can be installed directly into the canopy plenum or duct run. Therefore injecting ozone into the system and reducing cooking smells as quickly as possible.

When to choose UVC or Ozone?

Use ‘Ozone injection’ methods for moderate odour issues. Injection systems connect to the canopy plenum or duct work. Ozone is pulled into the ventilation system by the fan.

Units also known as ‘odour neutralisers’. Ozone breaks down odour molecules. It does not mask smells, it eliminates them. When independently tested ozone (as used in our Xtract units) successfully removes up to 90% of odours. [European Standard EN13725:2003 – Olfactometry.]

For high levels of odour use UVC and install in the duct or canopy. Within the duct, UVC light works at a higher intensity. When duct work is constantly exposed to the UVC light, the grease molecules break down. The number of lamps and units is changed to suit the air volume.

Any UVC system also creates ozone. Combining light energy and ozone, Plasma Clean UVC systems create a highly effective odour control system. In addition, light energy stops the build-up of grease in the duct.

Additional factors to consider

Pressure resistance – In duct systems add pressure to the system. Plasma Clean Techniclean units offer maximum efficiency with the lowest possible pressure resistance (<50pa). Xtract series (ozone injection systems) offer no pressure resistance.

Safety – interlock all UVC and ozone systems with air flow. They should never be on when the fan is off. Plasma Clean recommend a fan run on to flush any ozone out of the extraction system and prevent it falling back into the kitchen.

Turn the units off before opening or servicing. Install control panels, including an air pressure switch, to automatically turn the units off when filters and light guards are removed. Especially important for UV systems in canopies.

Ozone control – Surplus ozone requires treatment before it is discharged (DW/172 Guidelines Jan 2018). Especially when the discharge point is at low level (under 5m) or in a sensitive area (i.e. a courtyard, neighbours less than 20m away).

Activated carbon provides ozone control. Carbon breaks ozone (O3) down into oxygen (O2) before it discharges out of the kitchen ventilation system. Activated carbon increases the dwell time, giving the ozone longer to work on the odour molecules. Total number of carbon filters is based on the air volume of the system.

Using with Electrostatic Precipitators

Electrostatic Precipitators (ESPs) are not a primary means of odour control. ESPs remove particulate matter (such as grease, oil and smoke particles). Consequently an ESP combined with UVC or ozone units is a highly effective ‘pollution control’ solution.

Plasma Clean provide ESPs in various sizes. Available in stacked, double or triple pass arrangements. A complete grease, odour and smoke control in an integrated, packaged unit, Plasma Clean’s combined ESP/UV units remove up to 95% of particles and odours per pass.

Install UVC downstream of the ESP. For canopy UV systems install very efficient grease filters such as Coil Filters. Without adequate grease removal, the UVC lamps become coated and therefore lose efficiency. Remove larger particles first to ensure maximum output from the UVC system.

Conclusion

- UVC systems create ozone, use for grease and odour control.

- Ozone injection for moderate levels of odour whereas in duct UVC treats higher levels of odour.

- Treat grease and smoke first, then odour.

- Use ESPs for grease and smoke removal. ESPs have no effect on gaseous odours.

- Ozone injection (outside duct) or UVC (in duct or in canopy) have a low pressure drop.

- Size and quantity of equipment is based on air volume

- Use activated carbon for ozone control (where required).

You can find our more on our FAQ page. We also offer CIBSE accredited CPD Seminars on grease, odour and smoke control solutions. You can also contact the team – 0161 870 2325 or email [email protected]